Heat pumps have the ability to move heat energy from one environment to another, and in either direction. This allows the heat pump to both bring heat into an occupied space, and take it out. In the cooling mode of a heat pump works the same as an ordinary air conditioner (A/C). A heat pump uses an intermediate fluid called a refrigerant which absorbs heat as it vaporizes and releases the heat when it condenses. It uses an evaporator to absorb heat from inside an occupied space and rejects this heat to the outside through the condenser. The refrigerant flows outside of the space to be conditioned, where the condenser and compressor are located, while the evaporator is inside. The key component that makes a heat pump different from an A/C is the reversing valve. The reversing valve allows for the flow direction of the refrigerant to be changed. This allows the heat to be pumped in either direction.

Since the heat pump or refrigerator uses a certain amount of work to move the refrigerant, the amount of energy deposited on the hot side is greater than taken from the cold side. One common type of heat pump works by exploiting the physical properties of an evaporating and condensing fluid known as a refrigerant.

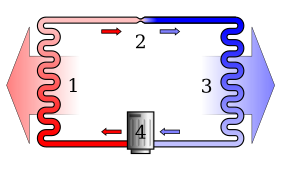

The working fluid, in its gaseous state, is pressurized and circulated through the system by a compressor. On the discharge side of the compressor, the now hot and highly pressurized vapor is cooled in a heat exchanger, called a condenser, until it condenses into a high pressure, moderate temperature liquid. The condensed refrigerant then passes through a pressure-lowering device also called a metering device like an expansion valve, capillary tube, or possibly a work-extracting device such as a turbine. The low pressure, liquid refrigerant leaving the expansion device enters another heat exchanger, the evaporator, in which the fluid absorbs heat and boils. The refrigerant then returns to the compressor and the cycle is repeated.

In such a system it is essential that the refrigerant reach a sufficiently high temperature when compressed, since the second law of thermodynamics prevents heat from flowing from a cold fluid to a hot heat sink. Practically, this means the refrigerant must reach a temperature greater than the ambient around the high-temperature heat exchanger. Similarly, the fluid must reach a sufficiently low temperature when allowed to expand, or heat cannot flow from the cold region into the fluid, i.e. the fluid must be colder than the ambient around the cold-temperature heat exchanger. In particular, the pressure difference must be great enough for the fluid to condense at the hot side and still evaporate in the lower pressure region at the cold side. The greater the temperature difference, the greater the required pressure difference, and consequently the more energy needed to compress the fluid. Thus as with all heat pumps, the Coefficient of Performance (amount of heat moved per unit of input work required) decreases with increasing temperature difference.

Insulation is used to reduce the work and energy required to achieve and maintain a lower temperature in the cooled space.

Due to the variations required in temperatures and pressures, many different refrigerants are available. Refrigerators, air conditioners, and some heating systems are common applications that use this technology.[citation needed]

Many heat pumps also use an auxiliary heat source for heating mode. This means that, even though the heat pump is the primary source of heat, another form is available as a back-up. Electricity, oil, or gas are the most common sources. This is put in place so that if the heat pump fails or can't provide enough heat, the auxiliary heat will kick on to make up the difference.

Geothermal heat pumps use the ground as a heat source and sink and water as the heat transport medium. They work in the same manner as an air to air heat pump, but instead of indoor and outdoor coils they use water pumped through earth materials as a heat transfer medium. These are very eco-friendly and are a cheaper alternative in the long run due to lower operating cost. Operating costs can be further reduced by storing summer heat in the ground for use during winter, and (for larger buildings requiring lots of air conditioning) by storing winter cold underground for use during summer.The two main types of heat pumps are compression heat pumps and absorption heat pumps. Compression heat pumps always operate on mechanical energy (through electricity), while absorption heat pumps may also run on heat as an energy source (through electricity or burnable fuels).[7] An absorption heat pump may be fueled by natural gas or LP gas, for example. While the Gas Utilization Efficiency in such a device, which is the ratio of the energy supplied to the energy consumed, may average only 1.5, that is better than a natural gas or LP gas furnace, which can only approach 1. Although an absorption heat pump may not be as efficient as an electric compression heat pump, an absorption heat pump fueled by natural gas may be advantageous in locations where electricity is relatively expensive and natural gas is relatively inexpensive. A natural gas-fired absorption heat pump might also avoid the cost of an electrical service upgrade which is sometimes necessary for an electric heat pump installation. In the case of air-to-air heat pumps, an absorption heat pump might also have an advantage in colder regions, due to a lower minimum operating temperature.ROBUR heat pumps comparison

A number of sources have been used for the heat source for heating private and communal buildings.[8]

Most commonly, heat pumps draw heat from the air (outside or inside air) or from the ground (groundwater or soil).[9] The heat drawn from the ground is in most cases stored solar heat, and it should not be confused with geothermal heat, though the latter will contribute in some small measure to all heat in the ground. Other heat sources include water; nearby streams and other natural water bodies have been used, and sometimes domestic waste water which is often warmer than the ambient temperature.[citation needed]

Air source heat pumps are relatively easy (and inexpensive) to install and have therefore historically been the most widely used heat pump type. However, they suffer limitations due to their use of the outside air as a heat source or sink. The higher temperature differential during periods of extreme cold or heat leads to declining efficiency, as explained above. In mild weather, COP may be around 4.0, while at temperatures below around −8 °C (17 °F) an air-source heat pump can achieve a COP of 2.5 or better, which is considerably more than the energy efficiency that may be achieved by a 1980's heating systems, and very similar to state of the art oil or gas heaters. The average COP over seasonal variation is typically 2.5-2.8, with exceptional models able to exceed 6.0 in very mild climate, but not in freezing climates. (2.8 kW).[10]

At least two manufacturers are selling heat pumps that maintain better heating output at lower outside temperatures than conventional air source heat pumps. These low temperature optimized models make air source heat pumps more practical for cold climates because they don't freeze to a stop that quickly. Some models however, defrost their outdoor unit electrically at regular intervals, which increases electricity consumption dramatically during the coldest weeks. In areas where only one fossil fuel is currently available (e.g. heating oil; no natural gas pipes available) these heat pumps could be used as an alternative, supplemental heat source to reduce a building's direct dependence on fossil fuel. Depending on fuel and electricity prices, using the heat pump for heating may be less expensive than fossil fuel. A backup, fossil-fuel heat source may still be required for the coldest days.

The heating output of low temperature optimized heat pumps (and hence their energy efficiency) still declines dramatically as the temperature drops, but the threshold at which the decline starts is lower than conventional pumps, as shown in the following table (temperatures are approximate and may vary by manufacturer and model):

| Air Source Heat Pump Type | Full heat output at or above this temperature | Heat output down to 60% of maximum at |

|---|---|---|

| Conventional | 47 °F (8.3 °C) | 17 °F (-8.3 °C) |

| Low Temp Optimized | 14 °F (-10 °C) | -13 °F (-25 °C) |

Ground source heat pumps, which are also referred to as Geothermal heat pumps, typically have higher efficiencies than air-source heat pumps. This is because they draw heat from the ground or groundwater which is at a relatively constant temperature all year round below a depth of about thirty feet (9 m). This means that the temperature differential is lower, leading to higher efficiency. Ground-source heat pumps typically have COPs of 3.5-4.0 at the beginning of the heating season, with lower COPs as heat is drawn from the ground. The trade off for this improved performance is that a ground-source heat pump is more expensive to install due to the need for the digging of wells or trenches in which to place the pipes that carry the heat exchange fluid. When compared versus each other, groundwater heat pumps are generally more efficient than heat pumps using heat from the soil. Their efficiency can be further improved, by pumping summer heat into the ground. One way is to use ground water to cool the floors on hot days. Another way is to make large solar collectors, for instance by putting plastic pipes just under the roof tiles or in the tarmac of the parking lot. The most cost effective way is to put a large air to water heat exchanger on the rooftop.

© All rights reserved